Introduction: The Path of Restoration

Restoring antique swords and armour is more than a craft. It is an act of respect. Each dent, each worn edge holds a story—a blade that once saw battle, a helm that shielded someone’s life. These are not just relics; they are echoes of courage, skill, and time. Our goal is not to make these artifacts new, but to make them whole; to bring back their spirit without rewriting the past.

Every tool we use, every moment of care, is guided by patience, precision, and purpose. Like in the dojo, we move with intention—quiet hands, steady eyes. Restoration becomes a dialogue across centuries: we listen, we learn, we honor what remains and reveal what was nearly lost. This path is slow, demanding, and utterly worthwhile.

Respecting the Past: Our Philosophy

At BushidoShop.nl, we believe history deserves reverence. Every item we restore tells a story, and we listen carefully before we act. Our restoration methods are guided by tradition. The craftsmanship from the past isn’t overwritten—it is revealed. With every decision, we work alongside the original maker’s intent, never against it.

We study each piece, considering its era, its use, and its meaning. Materials and techniques are matched with care; nothing is rushed, and nothing is done without purpose. This is not mere nostalgia—it is deep respect. By preserving these artifacts with discipline and integrity, we honor what came before. Restoration, to us, is a form of quiet devotion: to history, to craft, and to truth.

Assessing the Artifact: Listening Before Action

Before any restoration begins, we listen. Each artifact tells a story, and our first task is to hear it clearly. Careful observation reveals its form, wear, and even its silences. We scrutinize materials, joinery, and tool marks—all offering clues to origin and intent.

Our process includes thorough research: we reference the relevant period, check maker’s signatures, and study regional techniques. Experts are consulted, known examples compared, and no detail is considered too small. Authenticity is never assumed; it is earned, verified fact by fact.

Next, we assess the artifact’s condition. Repairs, breaks, and finishes are noted. We ask: what changed over time? What damage came from use, and what from neglect? This diligent examination guides our next steps. Restoration is never imposed; our choices align with the item’s truth, aiming to quietly return strength without rewriting history. Only after this deep listening do we act.

The Tools and Touch: Techniques Used

Restoration begins with understanding. Each artifact, whether knife, sword, or piece of armor, carries its own story—etched in steel and worn through use. Respecting that, our approach starts with gentle hands and sharp eyes.

The whetstone is our foundation: we favor natural stones, chosen for their grit, hardness, and character. Sharpening involves controlled, rhythmic strokes, an even pressure, and a carefully held angle. There is no rush. Polishing isn’t about mere shine; with fine-grit stones and sensitive fingertips, we coax out the blade’s unique grain and bring forward the subtle line between edge and body.

Rust removal is careful and deliberate. Using rust erasers, light abrasives, and a patient pace, we avoid harsh chemicals to ensure the blade stays true to its integrity. Handles are cleaned by hand. Wood receives natural oil nourishment, while micarta or horn is treated with a soft cloth and measured pressure. Cracks are mended with precision tools—small chisels, files, and adhesives carefully chosen for their subtlety.

Leather sheaths, too, are treated with respect: cleaned, reconditioned, and re-stitched as needed. Using awls, thread, beeswax, and steady discipline, each restoration preserves not just the object, but its history and spirit. Every tool becomes an extension of the hand, each technique a connection between craftsman and blade. Nothing is wasted, and nothing is hurried. The result is a restored piece, anchored in respect.

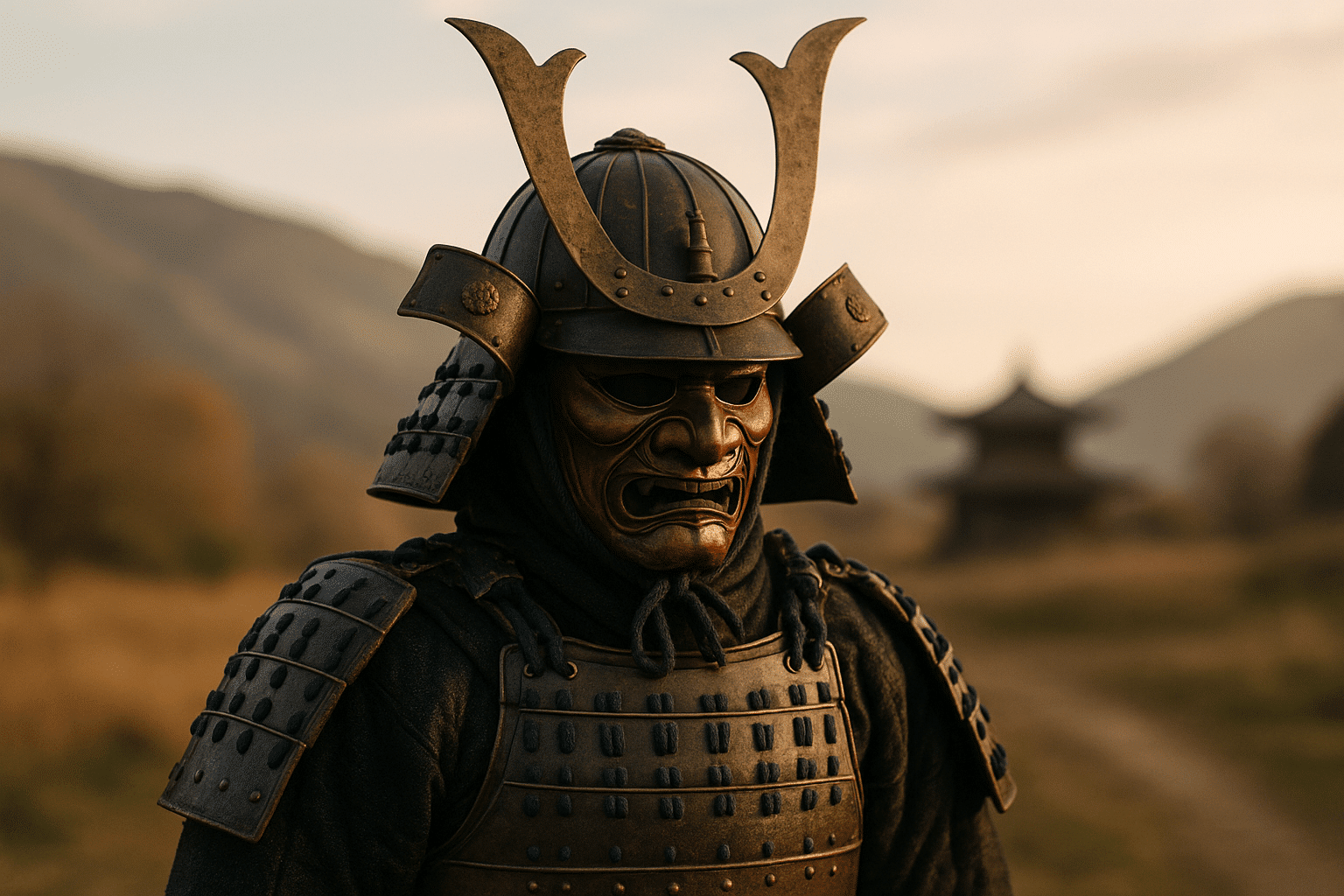

Armour Reborn: A Case Study

The cuirass arrived in a state of quiet ruin. Rust pitted the iron; lacquer peeled away; silk cords hung in fragile threads. Once belonging to a samurai from the late Muromachi period—mid-1500s—the armor bore the marks of time, not battle.

Our process began with meticulous documentation. We recorded every detail—measuring, cataloging materials, noting condition, and photographing from every angle to map the landscape of damage and decay. Disassembly followed, done with utmost care. Each plate, rivet, and hinge was individually removed, labeled, and nothing forced. Every step was recorded for continuity.

Cleaning came next, removing layers of embedded dirt with gentle precision. Oxidation was treated with care, and stabilization measures followed, halting any further loss. Reconstruction involved shaping missing parts to match existing material, always with reversible methods and no guesswork. Lacing demanded patience as silk cords were dyed to mirror the originals and threaded through ancient holes one at a time.

The finishing stage restored lacquer where appropriate, sealed the exposed metal, and reassembled the cuirass. The armor stood whole—but not new. Its scars and marks remained, keeping its story alive. Upright on its stand, not hidden behind glass, it returned as a worthy relic—honored, strong, and “reborn” through discipline, restraint, and care.

Sword Restoration: A Case Study

The katana arrived sheathed in rust, its blade dulled and pitted, the hamon—a line of steel’s temper—barely discernible. This sword had slumbered too long. Restoration began with unhurried patience. Each component was disassembled, catalogued, and examined. Rust removal was slow and guided by the natural grain of the steel. There were no shortcuts; the goal was to reveal, not erase.

Polishing came next, advancing through finer stones to gently coax the hamon back into view. Slowly, a curve like smoke reemerged—quiet, strong, and true. Attention then turned to the handle, where only traditional materials—samegawa (ray skin), silk, and wood—were used. Every wrap and fold was executed with the sword’s own story in mind, respecting tradition over modern convenience.

By the end of the process, the katana stood ready—neither artificially new nor left to decay. It was restored to its honest self, with history and character honored. Restoration, like swordsmanship itself, is about discipline over haste and above all, respect for what came before.

Preserving What Matters: Care After Restoration

The journey does not end when restoration is complete. In truth, it begins again. Every surface is sealed and stabilized, protecting against time, temperature, and touch. Finishes are carefully chosen for breathability and strength, always preserving the work’s original character.

Hardware is tightened, joints reinforced—nothing is left to chance. Each detail secures both weight and memory. We provide guidance for display and storage: setting appropriate light levels, controlling humidity, and encouraging mindful handling. These recommendations reflect respect, not restriction.

Thorough documentation is provided, including photographs, notes, and records of materials used. This ensures that if further work is ever required, the artifact’s story remains unbroken. Above all, we encourage use: to let restored pieces serve once more, to allow history to live on through engagement, not just preservation.